Understanding the Difference Between Pre-Galvanized and Hot-Dipped Barricades

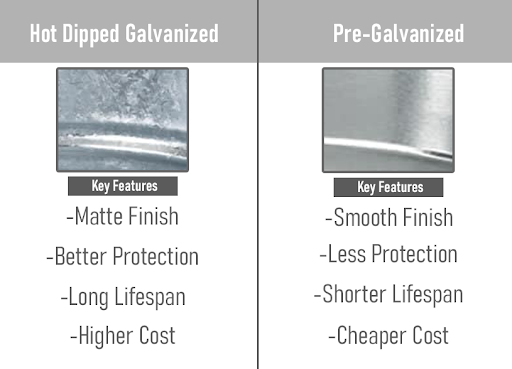

When it comes to selecting barricades for traffic control, construction sites, or event management, durability and longevity are key factors. One of the most important considerations is the type of galvanization used to protect the barricades from rust and corrosion. Two common methods of galvanization are pre-galvanization and hot-dip galvanization. While both processes aim to protect metal surfaces, they differ significantly in terms of application, durability, and cost. In this blog, we’ll explore the differences between pre-galvanized and hot-dipped barricades to help you make an informed decision.

What is Galvanization?

Galvanization is a process of applying a protective zinc coating to steel or iron to prevent rusting. Zinc acts as a sacrificial layer, meaning it will corrode before the underlying metal does, thereby extending the life of the product. The two most common methods of galvanization are pre-galvanizing and hot-dip galvanizing.

Pre-Galvanized Barricades

Pre-galvanization is a process where steel sheets or components are coated with zinc before they are fabricated into the final product, such as barricades. This is typically done by passing the steel through a bath of molten zinc or by electroplating. The zinc coating is usually thinner compared to hot-dip galvanizing.

Advantages of Pre-Galvanized Barricades:

- Cost-Effective: Pre-galvanizing is generally less expensive than hot-dip galvanizing because it requires less material and energy.

- Aesthetic Appeal: Pre-galvanized barricades often have a smoother, more uniform finish, making them visually appealing.

- Lightweight Coating: The thinner zinc layer makes the barricades lighter, which can be beneficial for transportation and installation.

Disadvantages of Pre-Galvanized Barricades:

- Less Durable: The thinner zinc coating provides less protection against corrosion, especially in harsh environments.

- Vulnerable to Damage: During fabrication (e.g., cutting or welding), the zinc coating can be compromised, leaving exposed areas prone to rust.

- Shorter Lifespan: Pre-galvanized barricades may not last as long as hot-dipped ones, particularly in outdoor or high-moisture environments.

Hot-Dipped Galvanized Barricades

Hot-dip galvanizing involves immersing the fully fabricated barricade into a bath of molten zinc. This process creates a thick, durable zinc coating that bonds metallurgically with the steel, providing superior protection.

Advantages of Hot-Dipped Galvanized Barricades:

- Exceptional Durability: The thick zinc coating offers excellent resistance to rust and corrosion, even in harsh weather conditions.

- Long Lifespan: Hot-dipped barricades can last for decades with minimal maintenance, making them ideal for long-term use.

- Complete Coverage: Since the entire barricade is dipped, even hard-to-reach areas are coated, ensuring uniform protection.

- Low Maintenance: The robust coating reduces the need for frequent repairs or replacements.

Disadvantages of Hot-Dipped Galvanized Barricades:

- Higher Cost: The hot-dip process is more expensive due to the amount of zinc used and the energy required.

- Heavier Weight: The thicker coating adds weight to the barricades, which can make them harder to transport and install.

- Rougher Finish: Hot-dipped barricades often have a rougher, less uniform appearance compared to pre-galvanized ones.

| Feature | Pre-Galvanized Barricades | Hot Dipped Galvanized Barricade |

|---|---|---|

| Coating Thickness | 10-20 microns | 45-100 microns |

| Durability | Moderate – suitable for mild conditions | High – ideal for extreme conditions |

| Lifespan | Up to 25+ years depending on conditions | Up to 50+ years depending on conditions |

| Cost | Lower | Higher |

| Cut Edge Protection | No, Exposted edges may rust | Yes, surrounding zinc protects exposed steel |

| Aesthetic Finish | Smooth and uniform finish | Rough/matte finish |

Which One Should You Choose?

The choice between pre-galvanized and hot-dipped barricades depends on your specific needs and budget. If you’re looking for a cost-effective solution for short-term use or indoor applications, pre-galvanized barricades may suffice. However, for long-term outdoor use in harsh environments, hot-dipped galvanized barricades are the better investment due to their superior durability and longevity.

Final Thoughts

Both pre-galvanized and hot-dipped barricades have their pros and cons. Understanding the differences between the two can help you choose the right option for your project. While pre-galvanized barricades are more budget-friendly and visually appealing, hot-dipped barricades offer unmatched durability and protection. Consider your environment, budget, and intended use to make the best decision for your needs. Investing in the right type of barricade can save you time, money, and effort in the long run.

If you want to see more products like the ones in this post be sure to check out our other Barricades

If you liked this post be sure to check out the blog on the CrowdMaster Barricade