What is a Dye Sublimation?

What is dye sublimation? In the world of printing and customization, dye sublimation stands out as a technique that revolutionized the way we transform ordinary materials into vibrant works of art. Whether you’re in the business of promotional products, custom apparel, or even home decor, understanding dye sublimation can unlock a realm of creative opportunities.

What is Dye Sublimation?

Dye sublimation is a printing process that utilizes heat to transfer dye onto materials such as fabric, metal, ceramic or plastic. Unlike traditional printing methods that only layer ink on top of a surface, dye sublimation infuses the dye directly into the material. This results in images that are more vivid, durable and resistant to fading, cracking or peeling.

The Science Behind Dye Sublimation

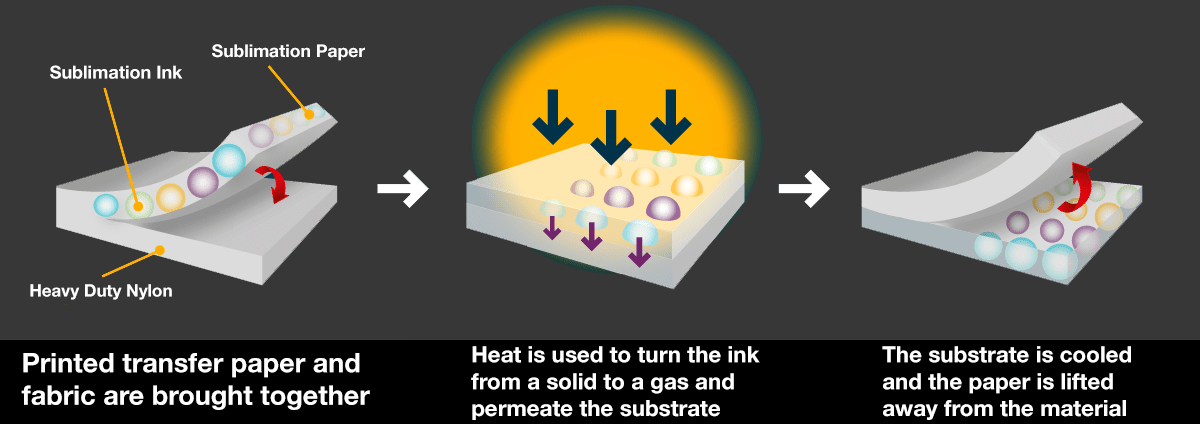

The term “sublimation” refers to the phase transition in which a substance changes from a solid to a gas without passing through the liquid state. In dye sublimation, solid dye particles are heated until they vaporize. The vaporized dye then permeates the material, solidifying back into a solid state and becoming part of the material itself.

This process involves three main stages, each with its own unique features:

Printing the Design: The journey of dye sublimation begins with the creation of a design. Using a high-quality inkjet printer equipped with special sublimation inks, the desired image or pattern is meticulously printed onto a special dye sublimation transfer paper. Moreover, the sublimation inks used are unique in the way they are designed. They are able to turn into gas under a specific heat and pressure condition. The design must be printed in reverse (mirrored) onto the transfer paper to ensure the final product appears correctly after the sublimation process occurs. This part of the process is the most crucial as any mistakes will be magnified in the final product.

Heat Press Transfer: The magic of dye sublimation happens in the heat press. The printed transfer paper is carefully positioned onto the substrate which in our case is heavy duty nylon woven in a herringbone pattern. Furthermore, ensuring that it aligns perfectly with the intended design area is crucial in making a perfect final product. After the two materials are positioned, a heat press machine then applies a combination of high temperatures (typically ranging from 250 to 400 degrees Fahrenheit) and pressure for a set period, usually between 30 to 60 seconds. This heat causes the inks to sublimate, transforming from a solid to a gas. The ink gas then penetrates the substrate, embedding itself deeply and permanently.

Cooling: After the sublimation process is finished, the substrate, which in this case is a belt, needs to cool down. As it cools, the dye transitions back from a gas to a solid state, now fully embedded within the fibers of the material. Additionally, this cooling phase ensures that the colors stabilize and the design sets properly. Once cooled, the transfer paper is peeled away, revealing a stunning, high-definition print.

Benefits of Dye Sublimation

Vibrant Colors: Dye sublimation produces incredibly vivid and rich colors, making it ideal for printing detailed designs onto our belts. Furthermore, the ability to capture fine details and subtle gradients ensures that every image looks as great.

Durability: The prints are resistant to fading, cracking, and peeling, even after multiple washes or extended exposure to sunlight. This makes dye sublimation perfect for products that need to withstand the test of time.

Versatility: Dye sublimation can be used on a wide range of materials, including polyester fabrics, coated metals, ceramics and certain plastics, however here at Crowd Control Depot we only use it for our nylon belts and mesh barricade covers.

Conclusion

Dye sublimation is a printing process that allows high definition printing on stanchion belts. This allows stanchions to be used for advertising, branding and safety messaging. As this is a dyeing process rather than printing surface ink the print won’t crack or wear due to the belt being retracted. As it is a digital process an unlimited number of colors can be printed, and this allows photos to be accurately reproduced and even barcodes printed. With its vibrant colors, durability, and versatility, this printing method is set to continue shaping the future of printing and customization. Call us today to learn how dye sublimation can be used to transform your stanchions into works of art!

If you want to see more products like this one be sure to check out our other Belt Stanchions

If you want to see more products like this one be sure to check out our other Safety Barriers